|

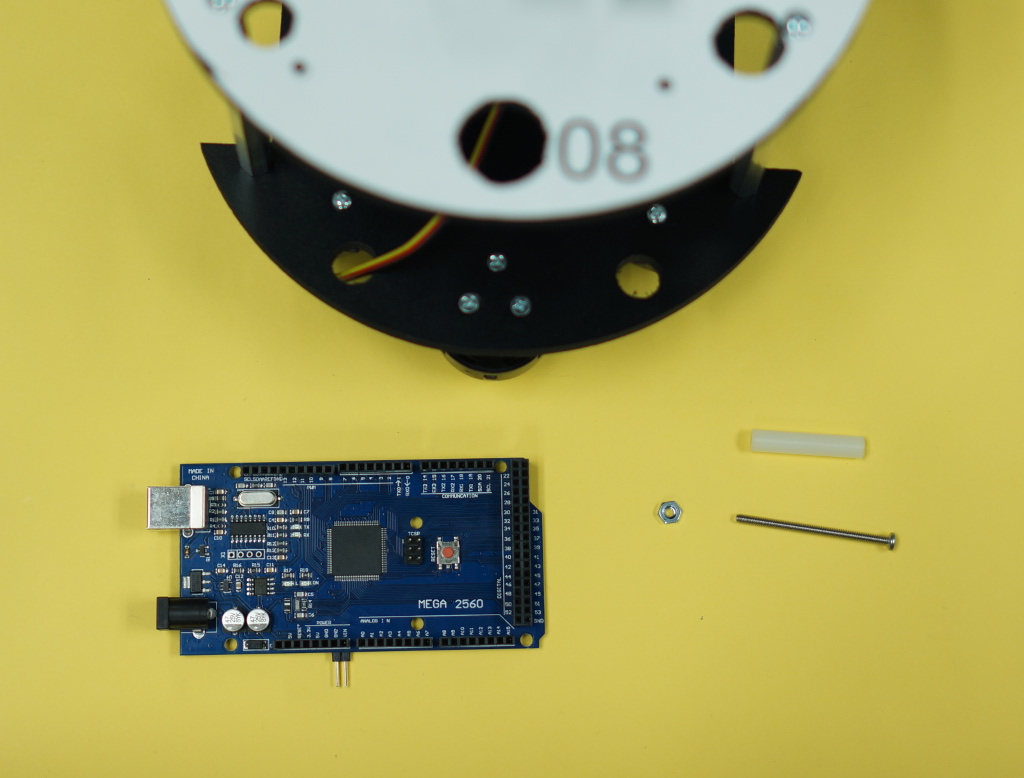

The first step of the Arduino Mega attachment is to lay out following items (shown in the image):

- Arduino Mega 2560

- One #4-40 1 3/4" (Arduino) Screw

- One #4 SPCR 1 1/4" (Arduino) White Spacer

- One #4-40 Hex Nut (Arduino)

- One #4 Washer (Arduino) (Same box as the Spacers)

At this point, you should have the parts laid out as depicted in the image to the right. (Washer not pictured)

|

Larger/Higher Resolution Picture

|

|

The second step is to attach the Mega to the top plate as shown.

- With the Flockbot facing away from you and the Ethernet port of the Mega facing to the left...

- Place the screw through the lower-left hole of the Arduino.

- Place the screw through the spacer.

- Put the washer between the spacer and the upper plate and run the screw through it.

- The purpose of this washer is to add 1/8" to the screw to even out the Mega.

- Attach the screw through the upper plate and secure with the nut.

- Make sure to screw it in tightly. It will hold position with just one screw.

Your space should look like the image on the right.

|

Larger/Higher Resolution Picture

|

Arduino Mega Sensor Shield Attachment

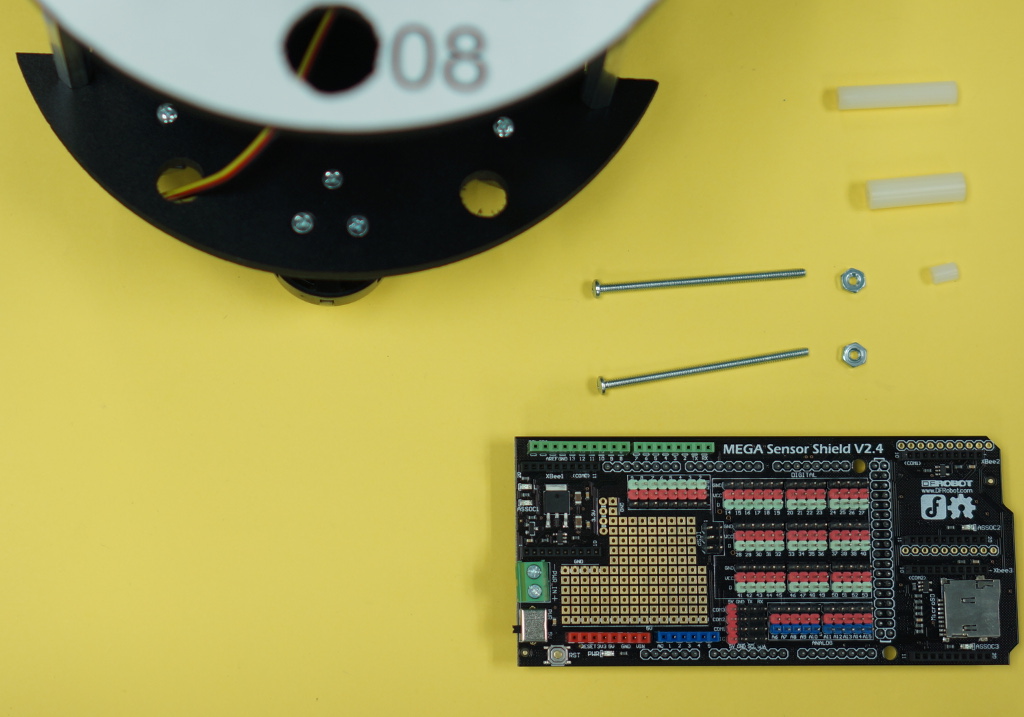

The first step of the Arduino Mega Sensor Shield attachment is to lay out following items (shown in the image):

- Sensor Shield

- One #4 SPCR 1 1/4" (Arduino) White Spacer

- One #4 SPCR 1" (Arduino) White Spacer

- One #4 1/4" Spacer (Rasp Pi) White Spacer

- Two #4-40 2 1/4" (Arduino) Screws

- Two #4-40 Hex Nut (Arduino)

- One #4 Washer (Arduino) (Same box as the Spacers)

At this point, you should have the parts laid out as depicted in the image to the right. (Washer not pictured)

|

Larger/Higher Resolution Picture

|

|

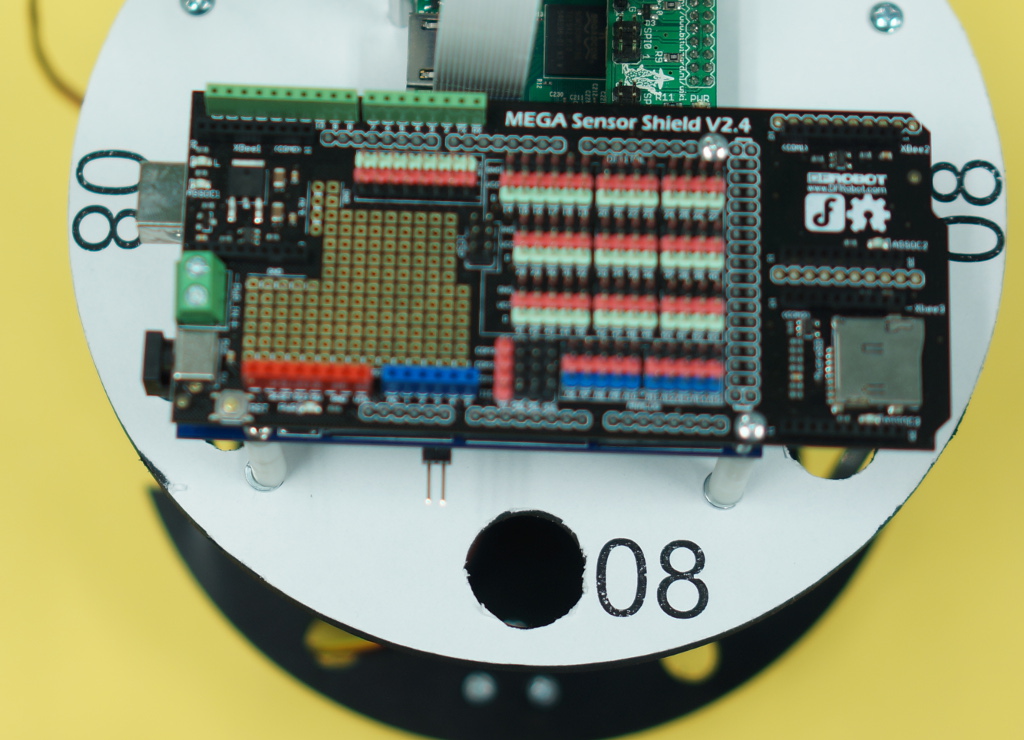

The second step is to attach the Mega to the top plate as shown. Again, with the Flockbot facing away from you.

- Align and attach the Sensor Shield to the Arduino Mega

- This will take a lot of even pressure and patience. There are a lot of pins.

- Be careful to do this evenly to avoid any bent pins.

- Attach the lower-right screw through the hole.

- Run the screw through the 1 1/4" riser.

- Put the washer between the spacer and the upper plate and run the screw through it.

- The purpose of this washer is to add 1/8" to the screw to even out the Mega.

- Run the screw through the Upper Plate and secure it with a nut.

- Place the small 1/4" spacer under the remaining hole in the Raspberry Pi

- Attach the upper-right screw through the hole.

- Feed the screw through the 1" riser, which will fit in the space between the Mega and the Raspberry Pi.

- At this point, continue feeding the screw through the Raspberry Pi and the 1/4" spacer between the Pi and the upper plate.

- Secure with the remaining nut.

Your space should look like the image on the right.

|

Larger/Higher Resolution Picture

|

|

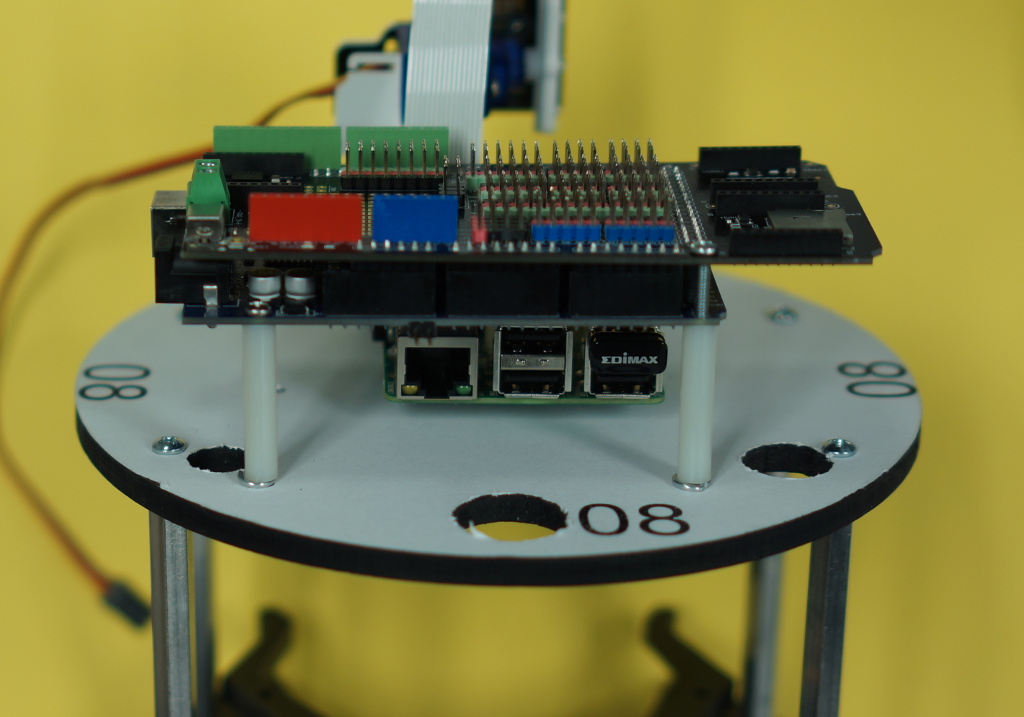

The same image from the side shows the two washers between the spacers and the upper plate.

|

Larger/Higher Resolution Picture

|

Flockbot Wheel Servo and Wheel Watcher Attachment

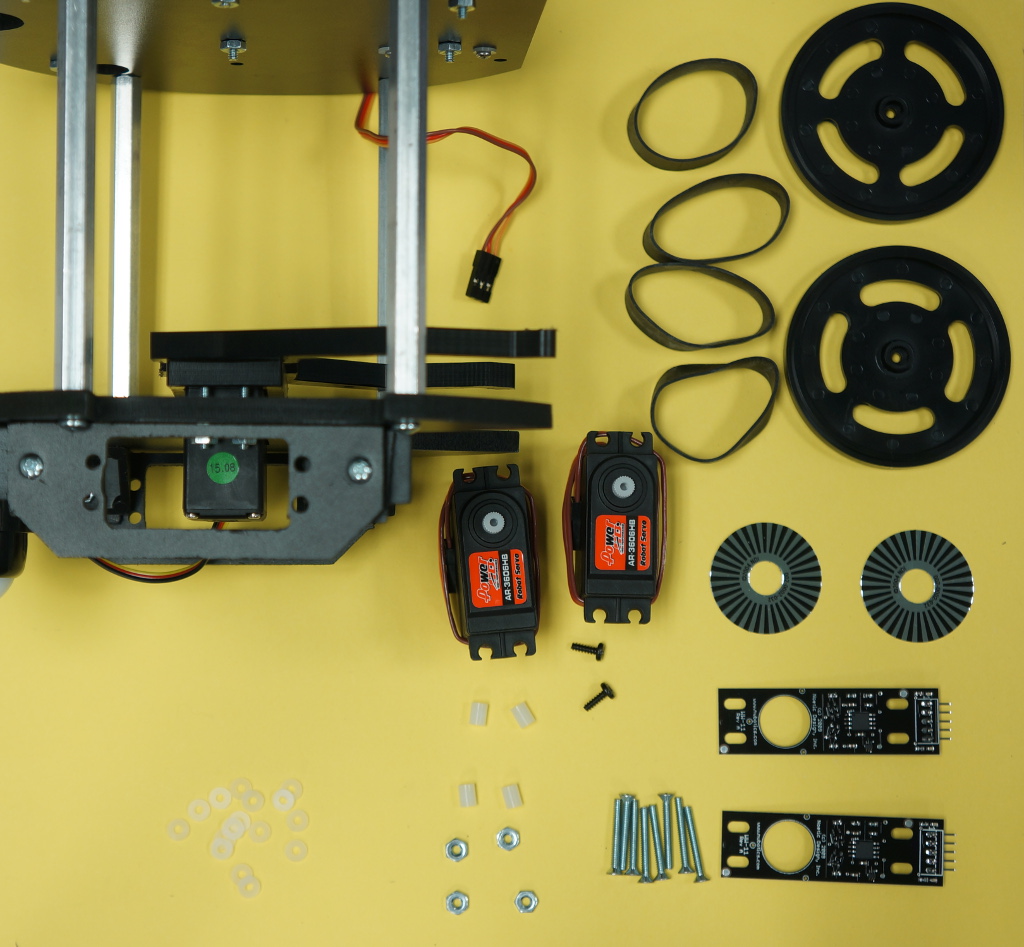

The first step of the Wheel Watcher attachment is to lay out following items (shown in the image):

- Two HD Wheel Servo

- Two WW-11 (Rev A) Boards

- Two Wheels (with 4 Rubber Bands)

- Two Black Servo Screws (In HD Wheel Servo Box)

- Two WW-11 Stickers

- Eight #4-40 Flat 7/8" Screws (Wheel)

- Four #4-40 Hex Nut

- Eight #4 1/4" Spacer (Rasp Pi)

- Sixteen #4 1/16 Spacer (Wheel)

At this point, you should have the parts laid out as depicted in the image to the right. (Washer not pictured)

|

Larger/Higher Resolution Picture

|

|

Now, you will be performing the following steps once for each side of the flockbot:

The second step is to attach the first HD Servo to the servo flange.

- Insert the Servo into the Flange as shown, with the servo wire facing the Front of the Flockbot

- Ensure the servo wire is coming out towards the front of the robot (Gripper side)

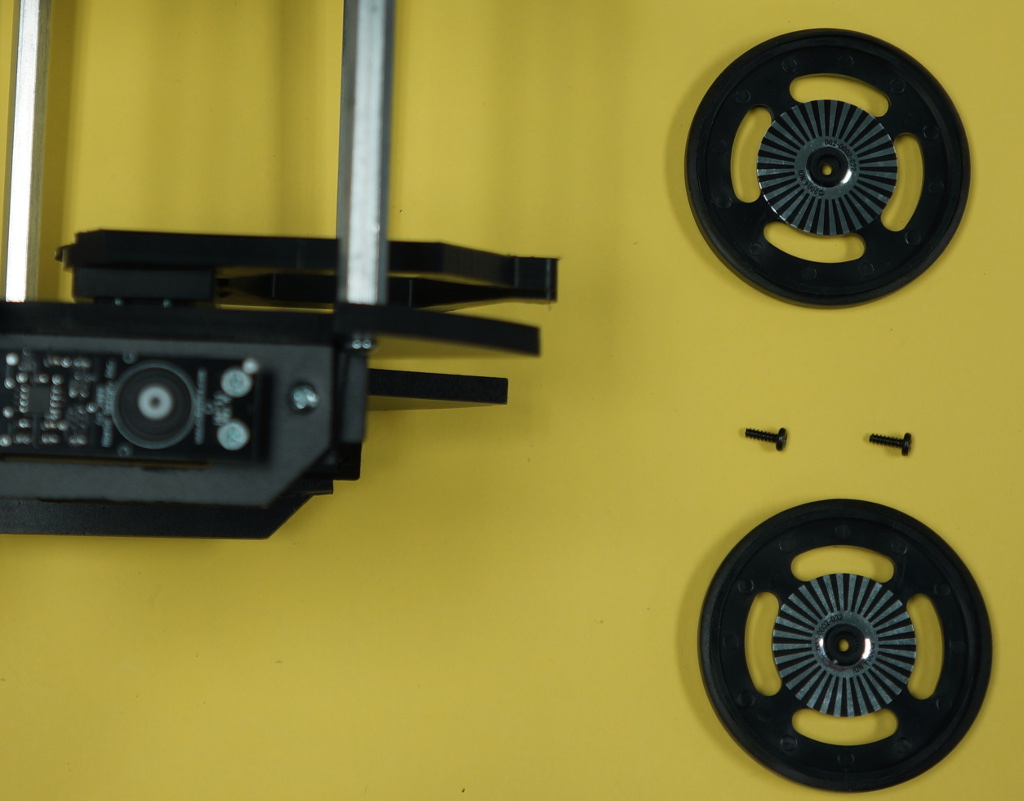

- Place the WW-11 over the servo as shown.

- Use the provided WW Alignment Tool (plastic disk) to align the WW-11 with the Servo

- Attach the WW-11 as follows (May be adjusted to perform the build easier):

- Insert the #4-40 Flat 7/8" Screw through the four holes of the WW-11

- Between the WW-11 and the Servo needs to go:

- One #4 1/4" Spacer (Rasp Pi)

- Two #4 1/6" Spacer (Wheel)

- When inserted properly, the spacers should take up all of the room between the WW-11 and the Servo.

- This will ensure a properly tightened screw.

- Now, attach the #4-40 Hex Nut to the back side of the servo to complete the mount.

Your space should look like the images on the right.

|

Larger/Higher Resolution Picture

|

|

|

Larger/Higher Resolution Picture

|

|

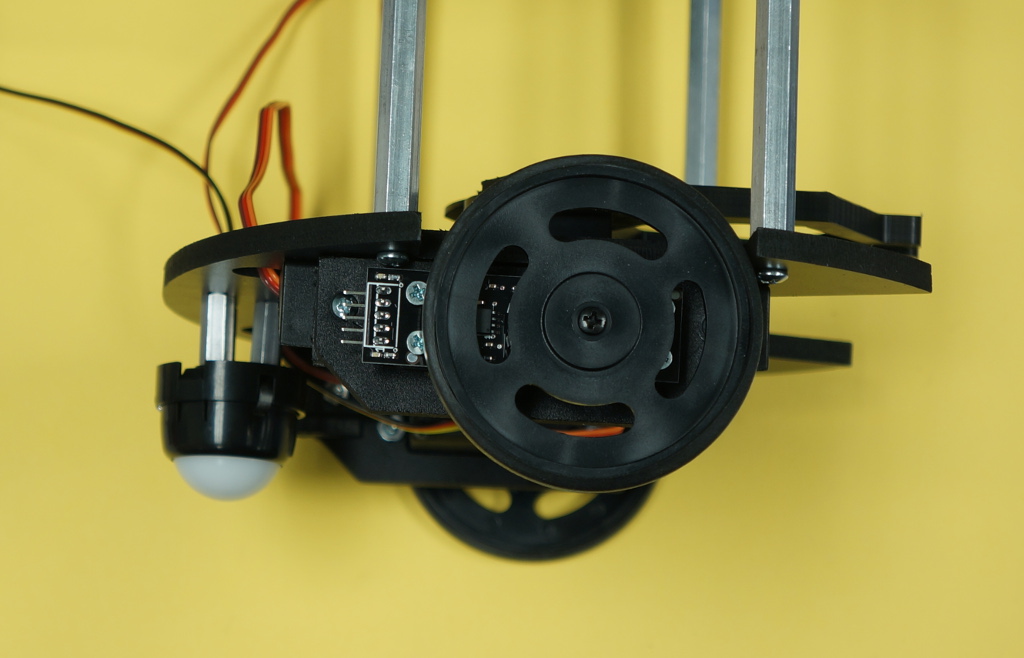

Now, perform the wheel construction:

- First, apply the stickers to the inside of the wheels.

- Second, attach the wheel on to the servos with the Black Servo screws.

|

Larger/Higher Resolution Picture

|

|

|

Larger/Higher Resolution Picture

|

|

Continued in Construction Three (Power Circuit)

|